Why Shrine?

Our Services

Investment Casting

Shrine Steelmelt produces investment casting components using carbon steel, low-alloy steel, and stainless steel grades, in addition to a wide variety of non-ferrous metals such as aluminum. We also perform necessary secondary operations on the cast parts such as finish machining, heat treatment, and surface treatment.

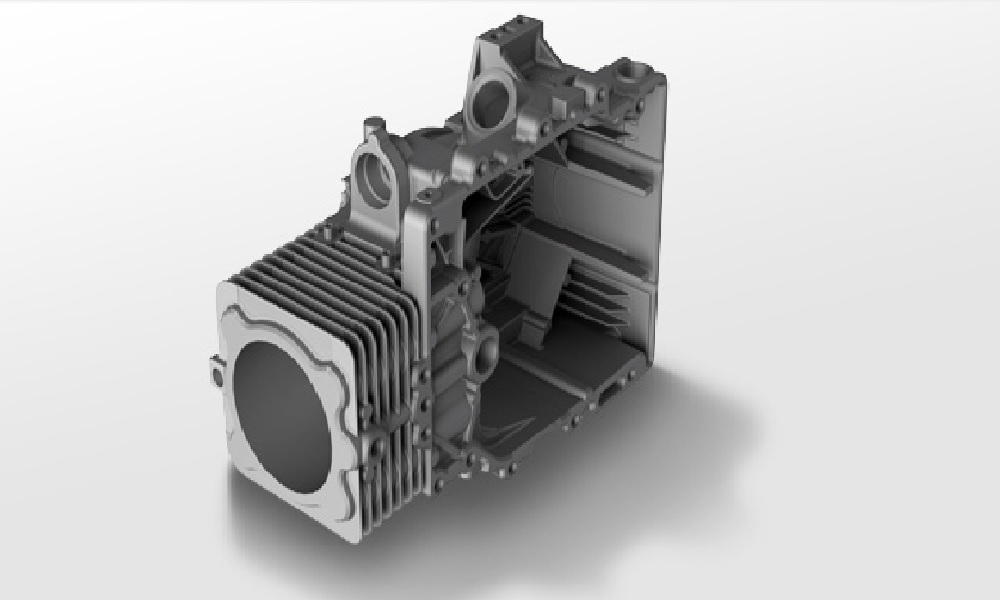

Sand Casting

Shrine Steelmelt produces Sand casting components using carbon steel, low-alloy steel, and stainless steel grades.We also perform necessary secondary operations on the cast parts such as finish machining, heat treatment, and surface treatment.

Forging

Shrine Steelmelt offers a variety of forging types, including drop forging, hot/cold forging, rolled ring forging, and press forging. We provide forged parts using lower-alloy and carbon steels, as well as alloys of aluminum. Once forged, components can be post-processed by precision CNC machining and surface finishing.

Machining

Shrine Steelmelt provides high-quality, tight toleranced components machined from bar stock. Shrine Steelmelt also finishes as-cast and as-forged components. Shrine Steelmelt can provide a range of materials, from soft aluminum and brass to hard titanium and cobalt-chrome alloys.

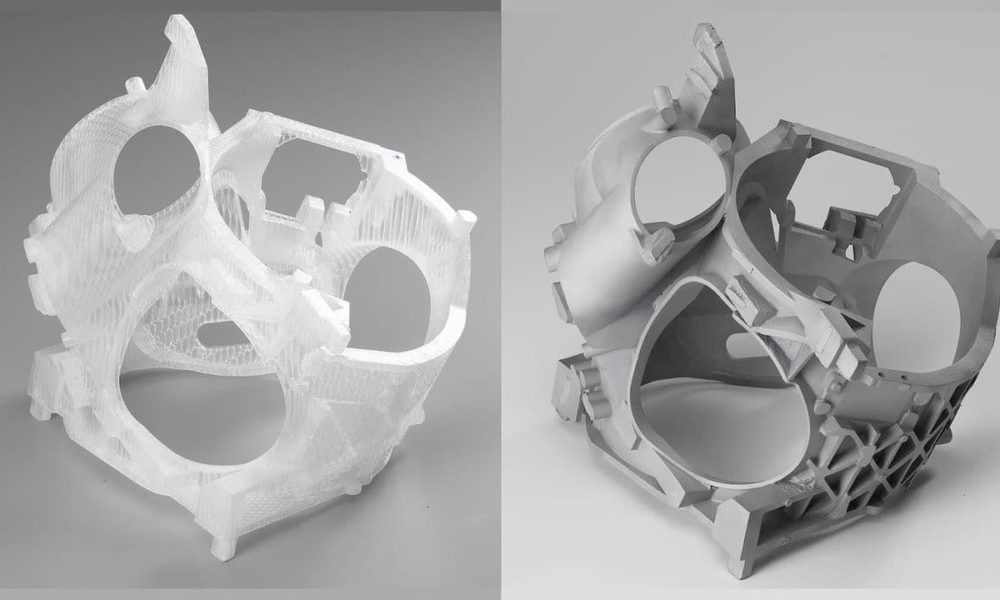

Prototyping & Production

Shrine Steelmelt help companies and entrepreneurs around the world manufacture prototypes for their businesses. There is no minimum order quantity, and your business can benefit from Shrine Steelmelt’s design and process expertise as well as our ability to quickly scale up production.

Pressure Die Casting

Shrine Steelmelt provides high-quality die-cast components produced using a range of materials including aluminum, zinc, copper, brass, and bronze alloys. Once a component has been die-cast, it can be further refined with CNC machining. Surface finishes are commonly applied through processes like shot-blasting, texturing, plating, and painting.

Our Vision

To be the world-class steel foundry with industry practices and technology with aiming to become a world best steel foundry.

Contact Us